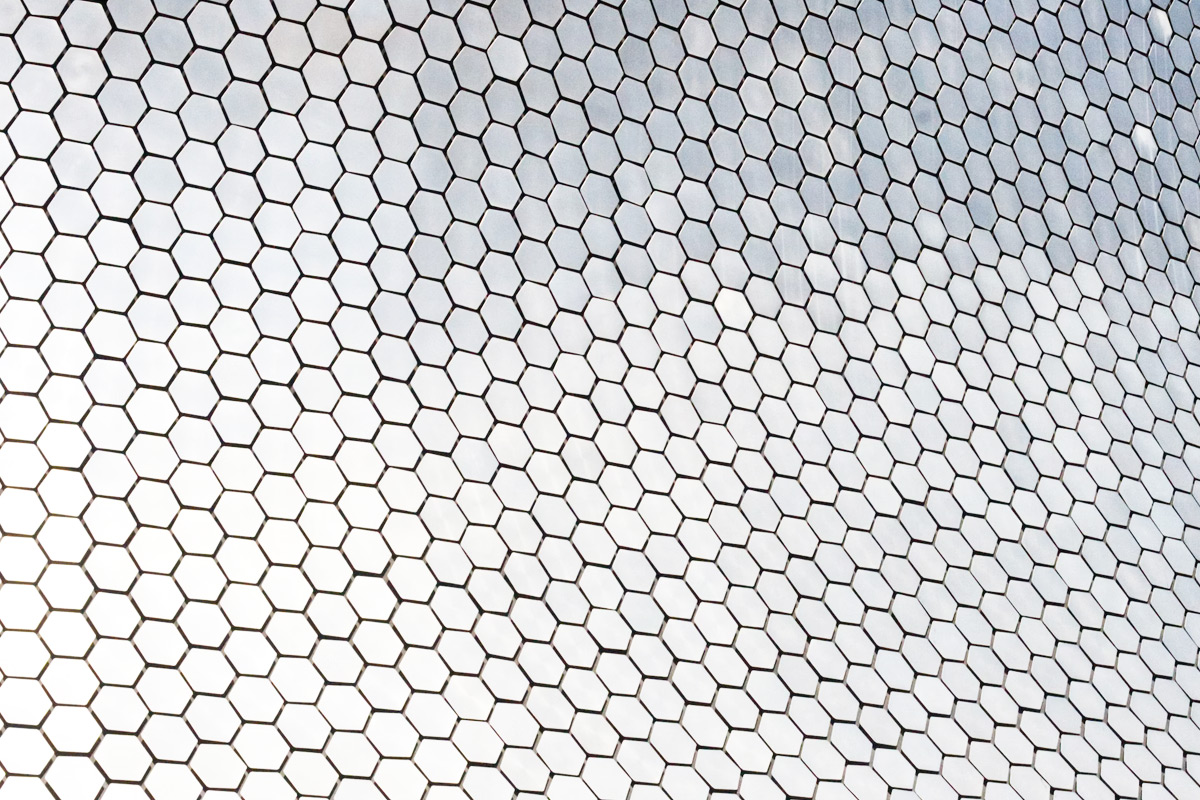

Appearance inspection of metal structural components

Detection items: bulging, deformation, scratches, hole deformation, indentation, bright printing, discoloration, watermarks, pits, oxidation, cracks, etc

Difficulty: Surface features are exceptionally complex, metal reflections, and defect samples are difficult to collect

Result: Accurate detection of various appearance defects, with a missed detection rate of less than 0.1%, significantly improving detection efficiency, and applied in batches to top large-scale manufacturing customers in China

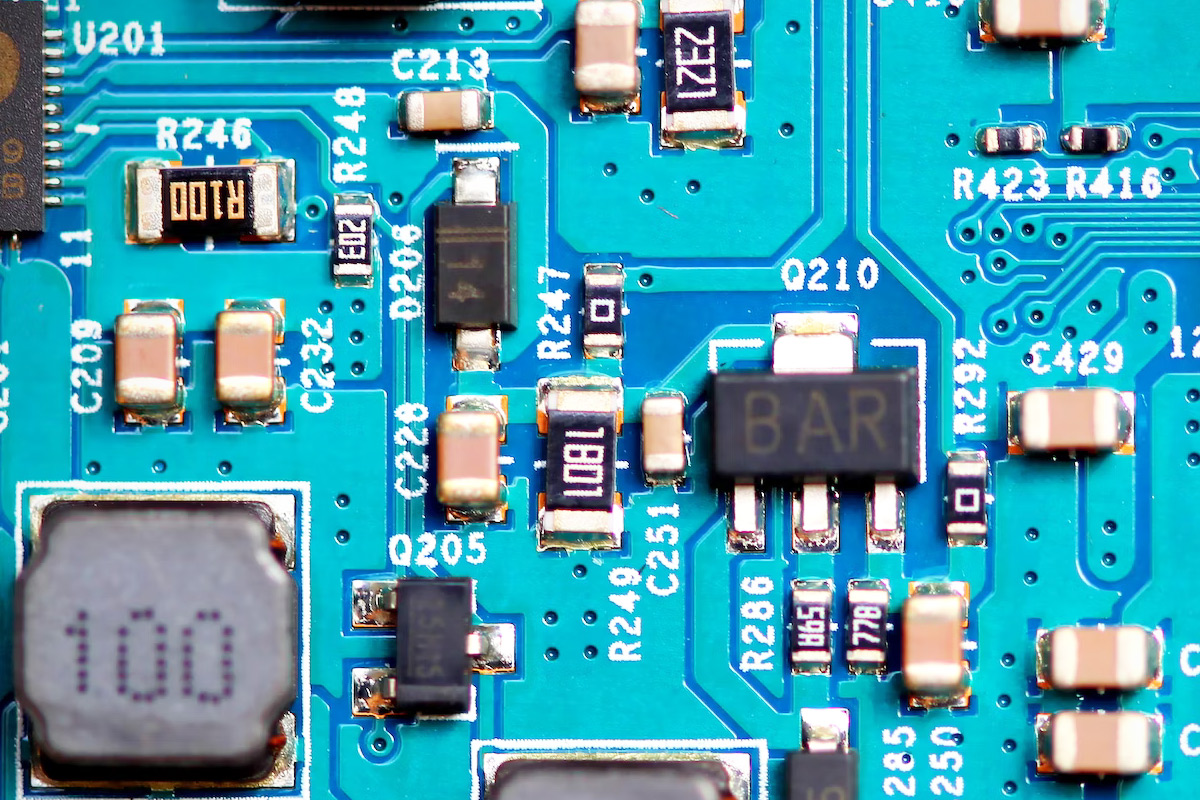

Appearance inspection of electronic components

Inspection items: defects such as damage, cracks, exposed copper, etc

Difficulty: diverse defect forms, complex surface textures, and high efficiency requirements

Result: Rapid and accurate detection of various surface defects in electronic components, with a missed detection rate of less than 0.1%, serving multiple leading large electronic component manufacturers

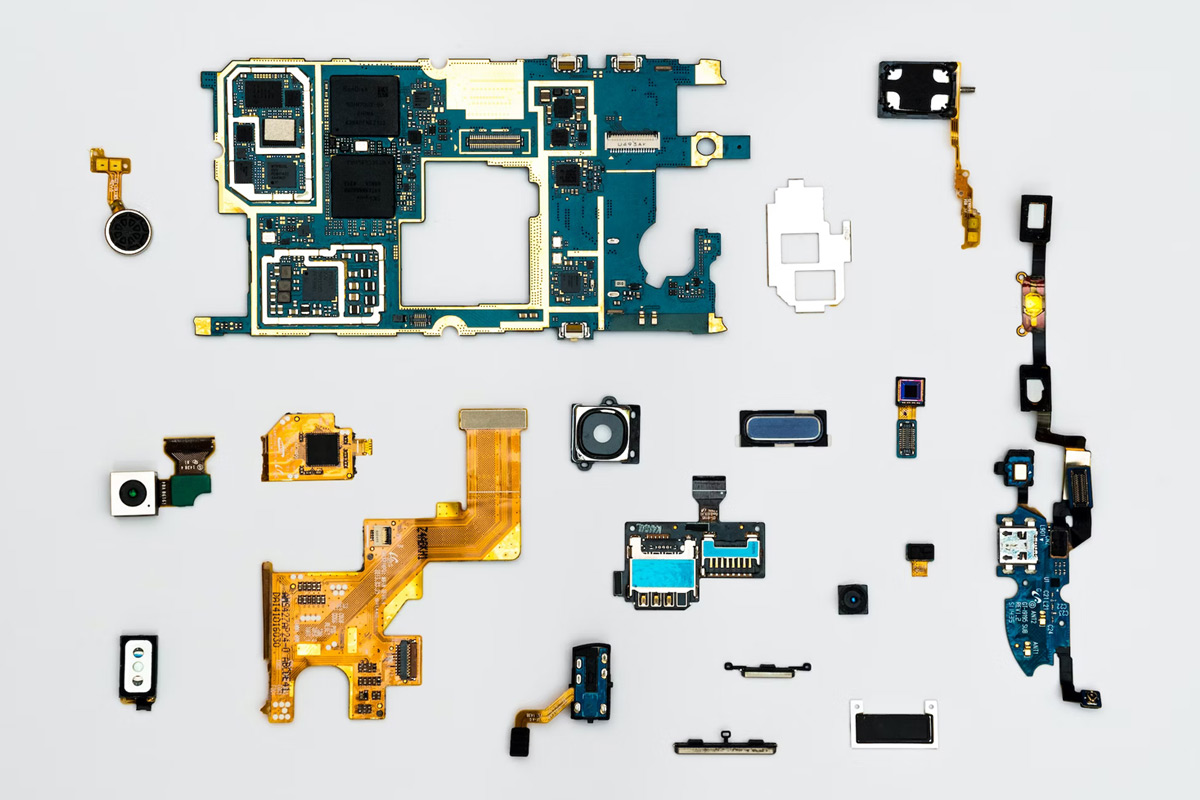

Semiconductor chip defect detection

Inspection items: shell damage, scratches, foreign objects, bubbles, missing pins, too short/long, scratches, bending, etc

Difficulty: The product size is small and there are many types of defects

Result: Accurately identify various defects, significantly reduce labor costs, and serve top semiconductor customers in China